Strategic Planning Challenges

Strategic Planning needs a lot of input from various stakeholders and is, therefore, the first and foremost challenge. The better the strategic planning, the better and more efficient the other planning steps and warehouse operations. If it is not done properly, you will have to struggle more with reactive tasks and fire fighting.

Let's pick out a couple of challenges:

Stakeholders are in Silos

The stakeholders who contribute to strategic planning are located in different departments: Management, intralogistics (warehouse operations), procurement, marketing, sales, facility management, etc. Many of them follow divergent goals, KPIs, and scorecards. Sales, for instance, focuses on order intake, procurement on purchasing the right amount of articles at the right time at the best prices. Marketing drives campaigns to boost sales or boost the brand (thereby boosting sales in the mid and long-run). What is the place where it all comes together? In the fulfillment center! Order increases must be handled just as efficiently as putting away tens of thousands of incoming goods resulting from a purchase deal. All this valuable information must be collected and regularly updated in the capacity plan. Unfortunately, that's not always the case. We have seen many fulfillment centers where the forecasts are not holding up to what they promise. Often, long-term capacity planning is done by copying "last year's spreadsheet" and adding some educated guesses to it. "In July next year, we will have a 10% higher order intake."

The Business Changes

Foreseeing exceptional situations like a pandemic or other large-scale catastrophes is hard. In such cases, joint planning and information become even more critical. More flexible working models can manage parts of the volatility, but that's quite limited in many countries by labor laws.

The Supply Chain Changes

As we have seen over the last 2.5 years and especially months, the supply chain has become unpredictable or even disrupted. Production sites are closing down; trade routes diminish due to low river water levels; stock market speculations cause chip shortages, and so on.

Tactical Planning Challenges

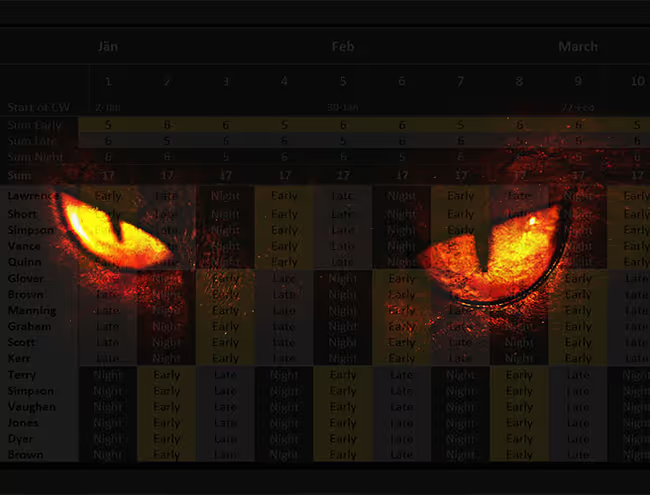

The tactical challenges are pretty similar to the strategic ones: The VUCA increases, and despite good strategic planning, things keep changing in the mid-term. E.g., orders increase or drop in a rainy summer or a weak holiday season, and we have to adjust the rosters accordingly. But what if we have approved people's vacations? We cannot simply revoke it. Generally, changing a roster on short notice might not be possible because labor laws prevent it.

Operational Planning Challenges

Even if we plan proactively, we know that the warehouse remains VUCA. The best plan cannot prevent numerous reactive changes throughout the weekly and daily operations. Often, intraday balancing is highly complex. One needs to balance (changing) orders, incoming haulers (early or late), sick leaves, technical downtimes, and more. The operational flow and efficiency depend on the knowledge and experience of the operational people. They know precisely how to handle fluctuations and exceptions. They sometimes know by watching the material flow or by listening to the sound of the plant that something is wrong and that they have to react.

Let's take an example:

- Customers place a surprising number of orders.

- The picking area needs more people.

- The picking team lead calls various people (other team leads, operations managers, etc.) and asks if anybody on their team has time and the right skills.

- This is usually a lengthy process because nobody knows precisely who is working where apart from the team leads. If you are lucky, sometimes, somebody adds the information to a spreadsheet and sends it around in several emails. If not, the changes go unnoticed.

- The other team leads have to play along in the first place if they are playing some tactics ("I keep them just in case...", "I need to hit my targets...", "nobody punishes me if two people too many work here..."), the search is in vain.

- The reasons why one needs to move people are not logged anywhere.

- The search and the decisions are not fact-based. It's primarily personal knowledge and experience.